Truck maintenance is key to ensuring your vehicles run safely and efficiently. This article offers essential tips and a checklist to help you keep your trucks in top condition and avoid unexpected breakdowns.

Key Takeaways

- Regular preventive maintenance is essential for fleet safety, compliance, and cost efficiency, significantly extending the lifespan of trucks.

- Creating a structured maintenance plan with a comprehensive checklist is crucial to track essential tasks like oil changes, brake inspections, and tire maintenance.

- Leveraging technology and maintaining detailed service history helps improve maintenance scheduling, reduce downtime, and enhance overall fleet reliability.

Understanding Truck Maintenance

Regular maintenance is the lifeline of any trucking operation. It’s not just about keeping the wheels turning but ensuring safety, compliance, and cost-efficiency. Routine maintenance can significantly extend the lifespan of your fleet, reducing unexpected failures and roadside assistance calls. A well-structured truck maintenance checklist ensures that every maintenance task is accounted for, helping you avoid costly fines and operational disruptions.

Preventive maintenance is the cornerstone of successful fleet management. Addressing minor issues before they escalate into major problems helps prevent accidents and enhances the overall safety of your vehicles. Ignoring maintenance can lead to increased operational costs and even accidents, making it essential to prioritize regular maintenance for your trucks.

What is Truck Maintenance?

Truck maintenance encompasses a range of tasks designed to keep vehicles in optimal condition, including:

- Preventive maintenance involving routine checks and services

- Changing engine oil

- Inspecting brakes

- Addressing fluid leaks

Truck manufacturer provide maintenance interval information to assist in effective maintenance practices.

A well-organized maintenance checklist helps track these tasks, ensuring nothing is overlooked. Keeping a detailed maintenance history, whether digitally or physically, is crucial for tracking vehicle upkeep and addressing potential issues promptly.

Benefits of Regular Truck Maintenance

Regular maintenance offers numerous benefits, from enhancing fuel efficiency to preventing costly repairs. Adhering to a truck preventive maintenance checklist helps fleets avoid unexpected breakdowns and ensures reliable vehicle performance over time.

Regular maintenance also contributes to the longevity of trucks, helping them operate efficiently for longer periods. Ultimately, this proactive approach saves money and keeps your fleet running smoothly.

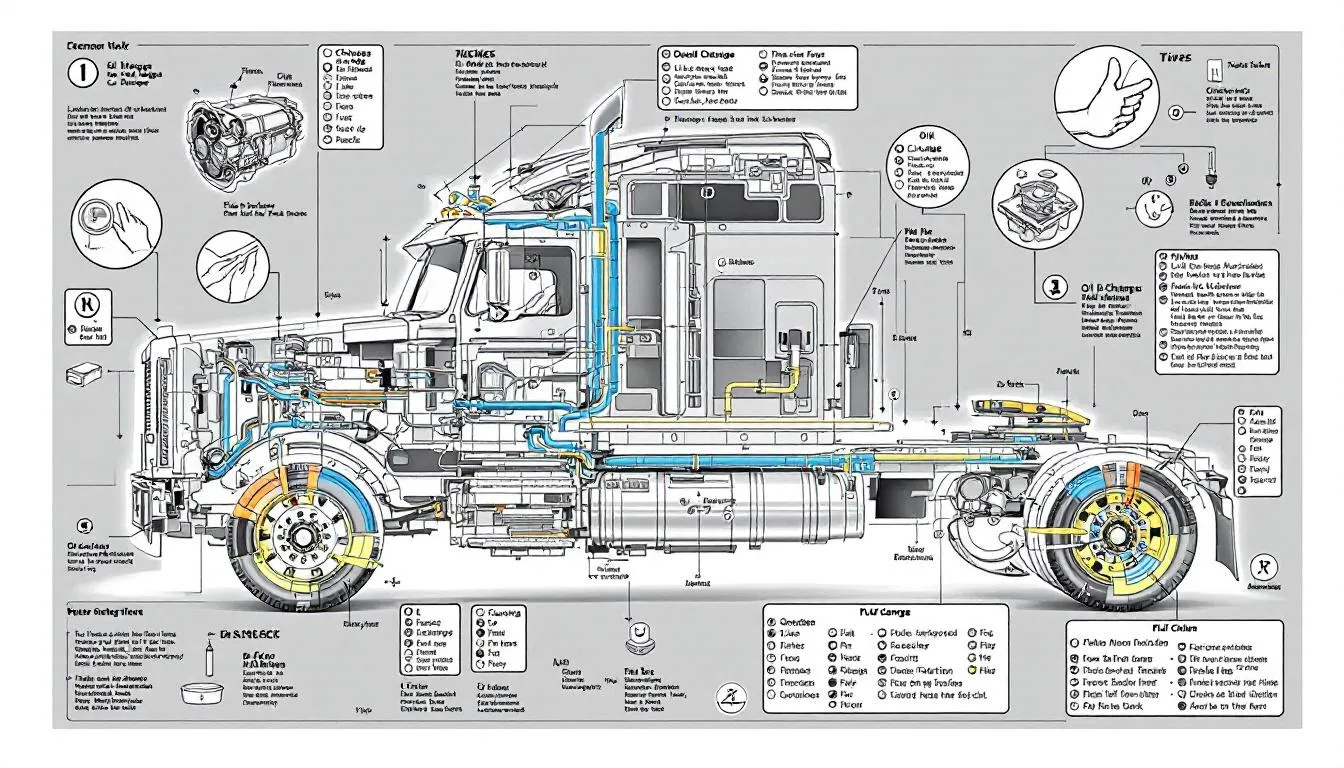

Essential Maintenance Tasks for Trucks

A comprehensive truck maintenance checklist is vital for keeping your fleet in top shape. This checklist should include both common and specialized maintenance tasks, ensuring all vehicle components are inspected and serviced regularly. From engine oil changes to brake system inspections, these tasks are essential for preventing serious damage and avoiding expensive repairs. Regular maintenance helps maintain safety standards and ensures compliance with regulations.

Neglecting proper maintenance can lead to unplanned breakdowns and excessive wear, significantly increasing operational costs. Establishing a preventive maintenance plan based on manufacturer recommendations and specific vehicle usage ensures timely and effective servicing.

Here are some essential maintenance tasks for trucks.

Engine Oil and Filter Changes

Changing the engine oil and filters on schedule is crucial for the longevity and performance of your truck’s engine. Regular oil changes maintain optimal engine lubrication, reducing wear and tear on engine components.

Including an oil change and oil filter changes in your truck maintenance checklist ensures that your vehicles run smoothly and efficiently, enhancing their overall lifespan.

Brake System Inspections

Regular braking system inspections are essential for maintaining safe stopping power and preventing accidents. Brakes are one of the fastest-wearing parts of a truck, making frequent inspections vital for ensuring that all components, including brake lights and reverse lights, are functioning properly.

A comprehensive brake system inspection, performed every 60,000 miles, includes checking brake drums, rotors, and brake pads to prevent costly repairs and ensure safety.

Tire Maintenance

Tire maintenance is crucial for both safety and fuel efficiency. Key aspects include:

- Monitoring tire pressure and tread depth to enhance vehicle performance and prevent blowouts.

- Maintaining correct tire pressure to optimize fuel consumption.

- Regularly checking for uneven wear, which can indicate alignment or suspension issues that need addressing.

Including these checks in your truck preventive maintenance checklist is essential for fleet efficiency.

Cooling System Checks

Maintaining the cooling system is vital to prevent engine overheating and ensure the proper operation of the vehicle. Regular checks should include:

- Inspecting the radiator for leaks or cracks

- Checking belts for leaks or cracks

- Examining hoses for leaks or cracks

- Ensuring to replace coolant at the correct level.

These checks are particularly important during hot weather to keep your trucks running smoothly and efficiently.

Air Filter Maintenance

Routine maintenance of air filters is essential for optimizing fuel efficiency and protecting the engine from damage. Regularly cleaning or replacing air filters according to the manufacturer’s recommendations helps maintain proper airflow and prevents contaminants from entering the engine.

Including air filter maintenance in your preventative maintenance plan ensures your trucks operate at peak performance.

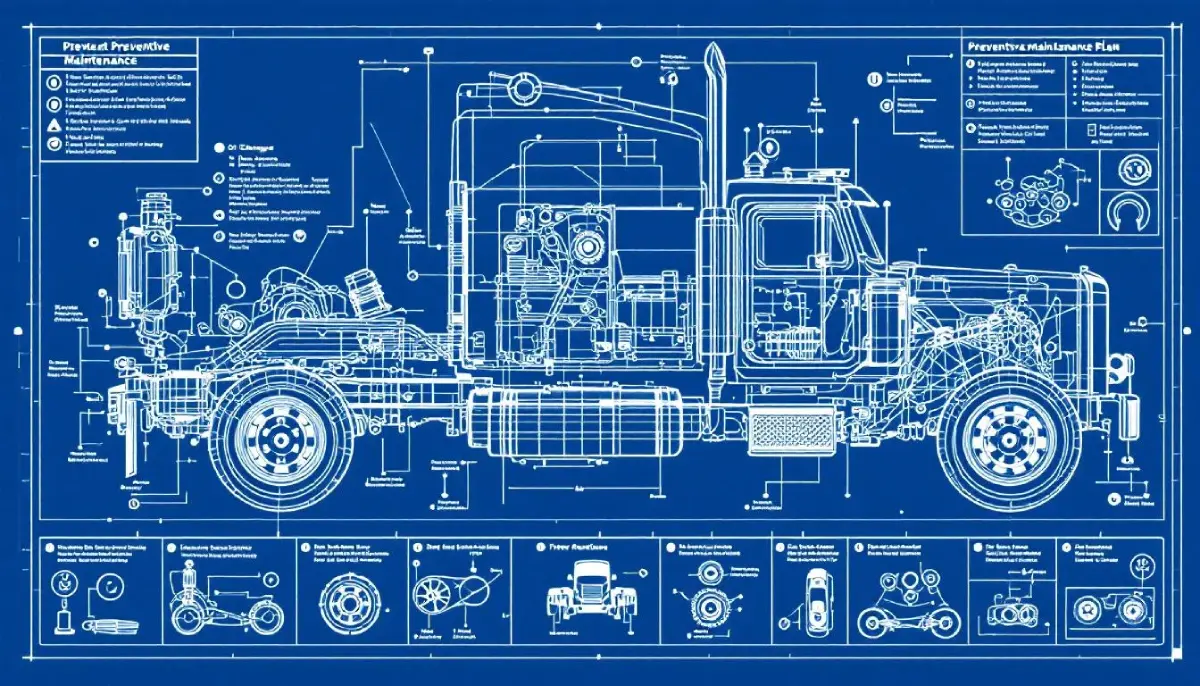

Creating a Preventive Maintenance Plan

A well-structured preventive maintenance plan is the backbone of efficient fleet management. It involves:

- Scheduling recurring inspections and services to prevent equipment failures and ensure vehicles remain in top condition.

- Defining maintenance goals and following best practices when establishing the plan to ensure its effectiveness.

- Using a comprehensive truck maintenance checklist to organize maintenance tasks and ensure no critical aspects are overlooked.

Adjusting maintenance strategies according to seasonal shifts is vital for maintaining optimal vehicle performance and reliability. Incorporating a preventive maintenance checklist tailored to your fleet’s specific needs allows for scheduling tasks in advance, enhancing operational efficiency.

Let’s explore how to create a customized maintenance schedule, track maintenance history, and utilize technology for maintenance.

Customizing Your Maintenance Schedule

Customizing your maintenance schedule based on your fleet’s usage patterns and the manufacturer’s recommendations is essential. Regular reviews of these recommendations help ensure maintenance tasks align with the vehicle’s actual usage and condition.

A mileage-based maintenance schedule is beneficial for trucks, with intervals varying based on the vehicle’s age and usage. Grouping vehicle maintenance tasks together can save time and streamline inspections, making the process more efficient.

Tracking Maintenance History

Maintaining a comprehensive service history is crucial for identifying patterns that predict future maintenance needs. Analyzing maintenance records allows managers to efficiently schedule future maintenance, reducing downtime and improving fleet reliability.

A solid maintenance history not only enhances truck performance but also ensures the safety and longevity of the entire fleet.

Utilizing Technology for Maintenance

Fleet management software enhances maintenance tracking by automating service reminders based on actual vehicle usage. Utilizing software can streamline the approval process for service tasks, leading to better cost control.

Mobile applications facilitate better communication between drivers and fleet management regarding maintenance issues, ensuring proactive maintenance strategies that significantly lower overall maintenance expenses.

Seasonal Maintenance Considerations

Adjusting maintenance practices according to seasonal changes helps keep trucks running smoothly year-round. Regular seasonal maintenance adjustments enhance vehicle safety and compliance while contributing to the overall longevity and efficiency of the fleet. Performing coolant system services and inspecting suspension components every 100,000 miles is essential to maintain truck performance across seasons.

Seasonal maintenance considerations ensure that your trucks are prepared to handle the unique challenges posed by different weather conditions. Let’s delve into specific maintenance tips for summer and winter.

Summer Maintenance Tips

During summer, regular inspection of AC components, including refrigerant levels and air pressure, is essential to ensure effective cooling. Verifying refrigerant levels and inspecting other AC components helps identify air leaks, allowing the air conditioning system to function optimally in hot weather.

Additionally, checking tire tread depth and condition is crucial, as hot weather can accelerate tire wear. Summer readiness includes ensuring to inspect tires and that they are in good condition to withstand heat and maintain safety.

Winter Maintenance Tips

Using appropriate engine oils for cold temperatures improves engine start-up and efficiency during winter. Ensuring that the heating systems are functioning properly is crucial for maintaining comfort for the driver and preventing fuel system line freeze-ups.

Regularly checking the batteries for charge and functioning correctly is also essential, as cold weather can significantly reduce battery performance.

Fleet Safety through Maintenance

Preventive maintenance is crucial as it helps avoid major repairs and ensures the safe operation of vehicles. Proper adherence to maintenance regulations significantly impacts overall motor carrier safety and reduces crash rates. Regular brake inspections ensure brakes function properly, which is vital for fleet safety. A truck preventive maintenance checklist helps organize these tasks, keeping your fleet safe and compliant.

Fleet safety through maintenance isn’t just about the mechanical aspects; it also involves driver training and compliance with regulations. Let’s explore how these elements contribute to overall fleet safety.

Driver Training and Reporting

Pre-trip inspections by drivers are essential in identifying safety concerns before they escalate. Drivers should report safety-related issues such as:

- Tire problems

- Soft brakes

- Worn wiper blades

- Rough idle

- Misfires

- Windshield wipers

- Windshield cracks

- Body damage. Conduct daily pre trip inspections to ensure immediate reporting of maintenance issues, which minimizes repair costs and avoids potential breakdowns.

Fleet managers can improve reporting by integrating a mobile app for easy communication, which a fleet manager can utilize effectively.

Compliance with Regulations

Regular inspections and vehicle inspections are mandatory for ensuring safety, efficiency, and environmental standards. Compliance with federal and state regulations ensures that your fleet meets all necessary requirements and avoids costly fines.

Following a truck maintenance checklist helps maintain these standards and keeps your fleet in compliance.

Cost Management in Truck Maintenance

Managing maintenance costs is a critical aspect of fleet management. A diligent preventative maintenance routine leads to cost savings. It also ensures safer operations and reduces the likelihood of breakdowns. Maintaining a preventive maintenance schedule is essential for long-term profitability and operational efficiency. Companies should focus on reducing maintenance costs, improving reliability, and enhancing fuel efficiency when setting maintenance goals for their fleet.

The average daily cost of unplanned downtime vehicle downtime can range from $448 to $760, highlighting the importance of efficient maintenance. Efficient cost management involves balancing maintenance frequency with costs and comparing service providers for the best value.

Balancing Costs and Maintenance Frequency

Preventative maintenance helps lower the chances of significant repairs. It also aids in maintaining a consistent budget. Balancing maintenance frequency with costs is crucial for fleet efficiency, allowing you to plan and allocate resources effectively.

Regularly reviewing and adjusting the frequent maintenance process schedules can help manage costs while ensuring vehicle reliability.

Comparing Service Providers

Comparing service providers is essential to ensure economic efficiency in truck maintenance and repairs. Key considerations include:

- Evaluating various service options to identify more cost-effective maintenance solutions for fleets.

- Utilizing national service networks to access a range of reliable service providers.

- Leveraging these networks to potentially secure better pricing.

Making informed decisions when selecting a service provider involves balancing cost against the quality of service, which are equally important.

Summary

In summary, regular truck maintenance is essential for ensuring the safety, efficiency, and longevity of your fleet. By following a truck preventive maintenance checklist, you can prevent costly repairs, enhance fuel efficiency, and maintain compliance with safety regulations. Creating a preventive maintenance plan tailored to your fleet’s specific needs is crucial for effective fleet management.

Maintaining a comprehensive service history, utilizing technology for maintenance tracking, and adjusting practices according to seasonal changes are all vital components of a successful maintenance strategy. By prioritizing preventive maintenance and cost management, you can keep your fleet running smoothly and efficiently. Remember, a well-maintained fleet is a safe and profitable fleet.

Ready to Take Your Fleet Safety to the Next Level?

While proper maintenance forms the foundation of fleet safety, comprehensive driver training is equally crucial for protecting your vehicles, drivers, and bottom line. At ImprovLearning, our specialized fleet safety training programs complement your maintenance efforts by equipping drivers with the skills and knowledge they need to identify potential issues, conduct thorough pre-trip inspections, and operate vehicles safely in all conditions.

Our proven training solutions help reduce accidents, lower insurance costs, and ensure regulatory compliance across your entire fleet. Learn more about our fleet training programs and discover how we can help you build a culture of safety that goes beyond maintenance checklists.

Frequently Asked Questions

What is the retention rate of information via interactive learning and regular reinforcement?

Interactive learning combined with regular reinforcement can enhance information retention by approximately 70%. This approach significantly improves retention compared to passive learning methods.

How often should oil be changed in a truck?

For optimal performance, you should change the oil in your truck every 10,000 to 15,000 kilometers or every six months, whichever comes first. Regularly following this guideline will help maintain your truck’s engine health.

What should be regularly checked to ensure a truck’s safety and efficiency?

Regularly checking tire pressure and wear is essential for maintaining a truck’s safety and efficiency. Prioritizing these checks can help prevent accidents and improve performance.

What must be maintained to prevent engine overheating in a truck?

To prevent engine overheating in a truck, it’s essential to maintain the cooling system. Regular checks and servicing will ensure optimal performance and avoid potential damage.

What should be done to ensure the brake system of a truck is safe?

To ensure the brake system of a truck is safe, it should be inspected and maintained regularly. This proactive approach will help identify potential issues before they become serious problems.

Live Chat

Live Chat